Master how to sharpen and maintain meat grinder blades with our comprehensive guide covering professional sharpening techniques, proper care methods, and expert maintenance tips. Learn essential strategies to keep your grinder blades razor-sharp, extend their lifespan, and ensure consistent grinding performance for all culinary applications.

Understanding Your Meat Grinder Blade System

Types of Meat Grinder Blades and Their Functions

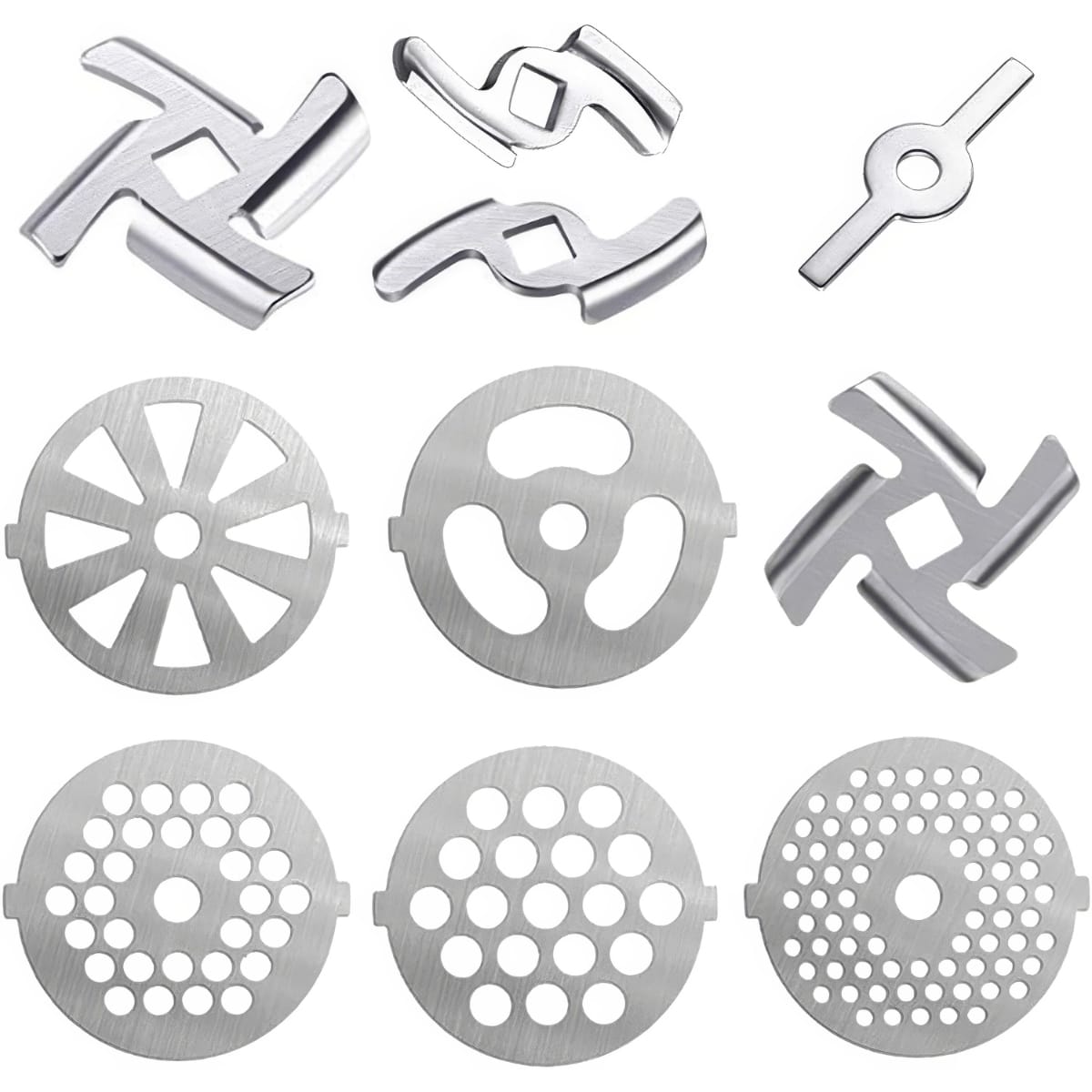

Modern meat grinders utilize a sophisticated cutting system consisting of multiple components that work together to create consistent results. The primary cutting blade, often called the knife blade, rotates against a stationary cutting plate to shear meat into uniform pieces. Understanding these components is essential when learning how to sharpen meat grinder blades and plates effectively.

Carbon steel blades represent the traditional choice for meat grinding applications. These blades hold an exceptionally sharp edge and are relatively easy to sharpen at home. However, they require more maintenance due to their susceptibility to rust and corrosion. Professional butchers often prefer carbon steel because it can be honed to razor sharpness, making it ideal for processing large volumes of meat efficiently.

Stainless steel blades offer superior corrosion resistance and are becoming increasingly popular in home applications. While they don’t hold as sharp an edge as carbon steel, they’re more forgiving for occasional users who might not maintain their equipment as rigorously. The trade-off is that stainless steel can be more challenging to sharpen and may require professional servicing more frequently.

Signs Your Meat Grinder Blades Need Sharpening

Recognizing when your blades need attention is crucial for maintaining optimal performance. The most obvious sign is when meat gets pushed instead of cut. Sharp blades slice cleanly through muscle fibers, while dull blades compress and push meat through the cutting plate, creating a paste-like texture that’s far from ideal.

Excessive heat generation during grinding indicates that your blades are working harder than they should. This friction not only reduces efficiency but can also raise the meat temperature to dangerous levels, promoting bacterial growth. Professional butchers monitor grinding temperature closely, as temperatures above 35°F can compromise both safety and quality.

Inconsistent grind texture is another telltale sign of blade degradation. When some pieces are properly cut while others remain in large chunks, your blade likely has dull spots or nicks that prevent uniform cutting. This inconsistency affects not just appearance but also cooking performance and food safety.

The grinding process should be smooth and efficient. If you notice increased grinding time and effort, with the motor working harder to achieve the same results, your blades are likely past their prime. Modern grinders are designed to process meat effortlessly when properly maintained, so any increase in resistance indicates maintenance needs.

How Often Should You Sharpen Meat Grinder Blades?

The frequency of blade sharpening depends heavily on usage patterns and the type of meat being processed. Home users processing occasional batches of ground meat might only need sharpening every 6-12 months, while professional operations running continuously may require weekly maintenance. Game processors who handle tougher, wilder meats often need more frequent sharpening than those processing tender domestic cuts.

Seasonal considerations play a significant role in maintenance scheduling. Hunting seasons create peak demand periods when processors handle large volumes of game meat, which is typically tougher and more challenging to grind than domestic meat. Many professional processors schedule major maintenance immediately before and after these busy periods to ensure optimal performance when it matters most.

Usage frequency guidelines suggest:

- Light home use (1-2 times monthly): Sharpen every 8-12 months

- Regular home use (weekly): Sharpen every 3-6 months

- Commercial use (daily): Sharpen every 1-2 months

- High-volume processing: Sharpen weekly or bi-weekly

Essential Tools for Meat Grinder Blade Maintenance

Sharpening Equipment You’ll Need

Understanding how to sharpen a meat grinder blade requires having the right tools for the job. Whetstones remain the gold standard for blade sharpening, offering precise control over the sharpening process. A complete whetstone kit should include coarse (400 grit), medium (800 grit), and fine (1000 grit) stones to handle everything from major blade restoration to final polishing.

When selecting whetstones, consider both natural and synthetic options. Arkansas stones, quarried from novaculite deposits, have been prized for centuries for their consistent grain structure and excellent sharpening properties. However, modern synthetic stones from manufacturers like King and Norton offer more consistent performance and are often more cost-effective for regular use.

Honing steel options provide an excellent middle ground between full sharpening and basic maintenance. A quality honing steel can restore a blade’s edge between major sharpenings, extending the time between intensive maintenance sessions. Diamond-coated honing steels offer superior performance but require more careful handling to avoid over-aggressive material removal.

For those wondering “can you sharpen meat grinder blades” with electric sharpeners, the answer is cautiously yes. However, electric sharpeners require careful selection and technique. Look for models with adjustable angles and gentle abrasive action. Avoid aggressive sharpeners designed for kitchen knives, as these can remove too much material and damage the blade’s geometry.

Sandpaper alternatives offer a budget-friendly option for blade maintenance. Use 220-400 grit wet sandpaper mounted on a flat surface for effective results. This method requires more patience but can achieve excellent results with proper technique. Always use waterproof sandpaper to prevent clogging and ensure smooth operation.

Cleaning and Maintenance Supplies

Proper cleaning is inseparable from effective blade maintenance. Food-safe cleaning solutions must be powerful enough to remove protein buildup and grease while remaining safe for food contact surfaces. A solution of warm water and dish soap handles most routine cleaning, while enzymatic cleaners excel at breaking down stubborn protein deposits.

Rust prevention products are essential for maintaining carbon steel blades. Food-grade mineral oil provides excellent protection when applied to clean, dry blades before storage. Avoid petroleum-based products that might contaminate food. Some professionals prefer specialized rust preventatives like Evapo-Rust for their superior performance and food safety credentials.

Proper storage containers protect blades from moisture and physical damage. Dedicated blade storage systems with individual slots prevent edge damage from blade-to-blade contact. For smaller operations, wrapping blades in cloth or storing them in blade guards provides adequate protection at lower cost.

Protective oils and lubricants serve multiple purposes in blade maintenance. Food-grade oils prevent rust, reduce friction during grinding, and help preserve the blade’s edge. Apply a thin film of oil to cleaned blades before storage, ensuring complete coverage without excess that might attract dust or debris.

Step-by-Step Guide: How to Sharpen Meat Grinder Blades

Preparation and Safety Measures

Before beginning any blade maintenance, proper preparation ensures both safety and effectiveness. Disassembly must be performed carefully to avoid injury and prevent damage to components. Always disconnect power before disassembly, and follow manufacturer instructions for your specific grinder model. Document the assembly process with photos if necessary, as proper reassembly is crucial for safe operation.

Safety gear requirements include cut-resistant gloves, safety glasses, and appropriate clothing. Grinder blades are incredibly sharp, and even dull blades can cause serious injury. Work gloves with cut resistance rating A2 or higher provide adequate protection for most operations. Safety glasses protect against metal particles that may be generated during sharpening.

Workspace setup contributes significantly to successful blade maintenance. Choose a well-lit area with adequate ventilation, especially when using chemical cleaners or lubricants. Ensure your work surface is stable and at comfortable height to prevent fatigue that might lead to accidents. Keep first aid supplies readily available, as cuts are the most common injury during blade maintenance.

Whetstone Sharpening Method (Recommended)

Learning how to sharpen meat grinder blades with whetstones represents the pinnacle of blade maintenance techniques. Begin by soaking the whetstone properly according to manufacturer instructions. Most stones require 10-15 minutes of soaking in clean water, though some synthetic stones need minimal soaking. Proper hydration ensures smooth cutting action and prevents clogging.

Angle maintenance is critical for effective sharpening. Meat grinder blades typically require a 15-20 degree angle on each side, creating a total included angle of 30-40 degrees. This angle balances sharpness with durability, providing excellent cutting performance while maintaining edge longevity. Use an angle guide if you’re learning, as consistency is more important than precision.

Sharpening stroke techniques determine the quality of your results. Use smooth, consistent strokes across the stone’s surface, maintaining steady pressure and angle throughout each pass. Start with the coarse stone to establish the basic edge geometry, then progress through finer grits to achieve the final polish. Count your strokes to ensure even treatment of both sides.

Testing sharpness levels helps determine when sharpening is complete. A properly sharpened blade should easily slice through paper without tearing. For meat grinder blades, test cutting performance on a piece of raw meat—the blade should cut cleanly without crushing or tearing the meat fibers. Remember that over-sharpening can be as problematic as under-sharpening.

Alternative Sharpening Techniques

Using sandpaper for blade maintenance offers an accessible alternative to whetstones. Mount waterproof sandpaper on a flat surface like glass or granite, starting with 220 grit and progressing to 400 grit for finishing. This method requires patience but can achieve excellent results with proper technique. Keep the sandpaper wet during use to prevent clogging and ensure smooth operation.

Electric sharpener considerations center around finding models appropriate for meat grinder blades. Look for sharpeners with adjustable guides and gentle abrasive action. Many kitchen knife sharpeners are too aggressive for grinder blades, potentially damaging the blade geometry. Test any electric sharpener on a spare blade before using it on your primary equipment.

Professional sharpening services offer expertise and equipment that may not be available to home users. Many knife shops and kitchen supply stores provide grinder blade sharpening services. Professional services typically cost $5-15 per blade but ensure optimal results and may include inspection for damage or wear that requires replacement.

Sharpening the Cutting Plate

Understanding how to sharpen meat grinder plates is equally important as blade maintenance. The cutting plate, or die, works in conjunction with the blade to create the final cut. Identifying wear patterns on cutting plates helps determine maintenance needs. Look for rounded edges around the holes, uneven wear patterns, or enlargement of the cutting holes.

Proper grinding techniques for cutting plates require specialized equipment or professional service. Unlike blades, cutting plates need their holes maintained to precise specifications. Home users can perform basic maintenance by carefully filing or sanding the cutting surface, but major restoration typically requires professional grinding equipment.

Maintaining hole integrity is crucial for proper grinder function. Enlarged or damaged holes create inconsistent grind sizes and can allow meat to pass through without proper cutting. Inspect holes regularly for damage, and replace plates when holes become significantly enlarged or damaged beyond repair.

Daily Maintenance Practices for Meat Grinder Blades

Pre-Use Preparation

Establishing a blade inspection checklist ensures consistent performance and prevents problems before they start. Visual inspection should identify any nicks, chips, or rust spots that might affect performance. Check blade mounting surfaces for damage or wear that could affect proper seating. Ensure cutting plates are properly aligned and securely mounted.

Proper assembly techniques prevent damage and ensure safe operation. Always follow manufacturer torque specifications when tightening components. Over-tightening can distort blade geometry, while under-tightening creates dangerous operating conditions. Use thread-locking compounds where specified to prevent loosening during operation.

Lubrication requirements vary by grinder type and manufacturer specifications. Food-grade lubricants protect moving parts and reduce wear. Apply lubricants sparingly to avoid contamination of ground meat. Some modern grinders are designed to operate without additional lubrication, so consult your manual before adding any lubricants.

During-Use Best Practices

Optimal grinding speeds balance productivity with blade longevity. Running grinders too fast generates excessive heat and accelerates blade wear. Most manufacturers specify optimal operating speeds, typically measured in RPM. Maintaining proper speed reduces blade stress and produces better grinding results.

Meat temperature considerations significantly impact blade performance and food safety. Meat should be kept at 32-35°F during grinding to prevent bacterial growth and ensure clean cutting. Warm meat tends to smear rather than cut cleanly, creating poor texture and potentially unsafe conditions. Many professionals partially freeze meat before grinding to optimize texture and safety.

Avoiding blade damage requires attention to what goes into the grinder. Remove bones, cartilage, and other hard materials that can nick or chip blades. Even small bone fragments can cause significant damage to sharp blades. Inspect meat carefully before grinding, especially when processing game meat that may contain shot or bone fragments.

Post-Use Cleaning Protocol

Immediate disassembly after use prevents protein buildup and bacterial growth. Don’t allow meat residue to dry on blades or cutting plates, as this creates ideal conditions for bacterial growth and makes cleaning more difficult. Disassemble components while they’re still warm to take advantage of easier cleaning conditions.

Thorough cleaning methods remove all traces of meat and grease. Use warm, soapy water for initial cleaning, followed by sanitizing solutions if required. Enzymatic cleaners excel at breaking down protein deposits that regular detergents might miss. Avoid abrasive cleaners that could damage blade surfaces or create micro-scratches that harbor bacteria.

Drying and storage procedures prevent rust and maintain blade sharpness. Thoroughly dry all components before storage, paying special attention to crevices where moisture might accumulate. Apply a light coat of food-grade oil to prevent rust, especially on carbon steel blades. Store components in a dry environment with adequate ventilation.

Long-Term Meat Grinder Blade Care

Proper Storage Techniques

Climate control considerations play a crucial role in blade longevity. Humidity levels above 60% can promote rust formation, especially on carbon steel blades. Store equipment in climate-controlled environments when possible, or use desiccants to control moisture levels in storage areas. Avoid temperature fluctuations that can cause condensation on metal surfaces.

Rust prevention strategies go beyond simple oiling. Proper storage containers with controlled atmosphere can significantly extend blade life. Vapor corrosion inhibitors (VCI) provide excellent protection for long-term storage. These products release protective vapors that form a molecular barrier against corrosion without leaving residues that might contaminate food.

Organizational systems prevent damage from handling and make maintenance more efficient. Dedicated storage for each blade size prevents confusion and reduces handling damage. Label storage areas clearly to ensure proper blade selection and inventory management. Consider implementing a rotation system for multiple blade sets to ensure even wear.

Seasonal Maintenance Schedules

Deep cleaning procedures should be performed at least annually, or more frequently for high-use equipment. This involves complete disassembly, thorough cleaning of all components, and detailed inspection for wear or damage. Deep cleaning provides an opportunity to address issues before they become serious problems.

Comprehensive inspections evaluate overall equipment condition and identify components nearing replacement time. Check for excessive wear, proper fit of components, and signs of fatigue or stress. Document findings to track wear patterns and optimize replacement schedules. Professional inspection may be warranted for high-value equipment or critical applications.

Replacement timing guidelines help optimize equipment performance and prevent unexpected failures. Replace blades when sharpening no longer restores adequate performance, or when damage compromises safety. Economic considerations should balance blade cost against labor and downtime costs. Keeping spare blades on hand prevents interruptions during peak processing periods.

Troubleshooting Common Blade Issues

Addressing rust and corrosion requires immediate action to prevent further damage. Light surface rust can often be removed with fine abrasives or chemical rust removers. More severe corrosion may require professional restoration or blade replacement. Prevention remains the best strategy, making proper storage and maintenance crucial.

Fixing nicks and chips depends on the severity and location of damage. Small nicks at the blade edge can often be removed during normal sharpening. Deeper damage may require professional repair or replacement. Large chips that affect blade geometry typically warrant replacement, as repair costs often exceed replacement costs.

Dealing with dull edges is the most common maintenance issue. Regular sharpening prevents excessive dullness that requires aggressive restoration. Establish sharpening schedules based on usage patterns and performance monitoring. Don’t wait until performance degrades significantly, as this makes restoration more difficult and time-consuming.

Professional Tips for Extending Blade Life

Meat Preparation Techniques

Proper meat cutting before grinding significantly impacts blade life and performance. Cut meat into strips that fit comfortably in the grinder throat without forcing. Oversized pieces create excessive stress on blades and can cause jamming. Remove sinew, gristle, and other tough connective tissues that can dull blades prematurely.

Temperature control importance cannot be overstated in professional meat processing. Maintaining meat temperature at 32-35°F ensures clean cutting and prevents bacterial growth. Use refrigerated storage and work in temperature-controlled environments when possible. Monitor meat temperature throughout processing to ensure consistent conditions.

Avoiding bone and cartilage prevents the most common cause of blade damage. Even small bone fragments can create significant nicks or chips in sharp blades. Inspect meat carefully, especially when processing game meat or working with less familiar cuts. When in doubt, err on the side of caution and remove questionable materials.

Grinding Technique Optimization

Feed rate management balances productivity with blade longevity. Feeding meat too quickly can overload the grinding mechanism and create excessive stress on blades. Maintain steady, consistent feeding rates that allow the grinder to operate smoothly. Modern grinders typically indicate optimal feeding rates through sound and vibration patterns.

Pressure application guidelines help prevent damage from excessive force. Let the grinder do the work—applying excessive pressure can damage blades and create poor grinding results. Use the meat pusher to guide meat into the grinding mechanism without forcing. Proper technique produces better results with less equipment stress.

Multiple-pass strategies can improve results while reducing blade stress. For very fine grinds, consider using a coarse plate first, then re-grinding with a fine plate. This approach distributes the cutting load and often produces better texture than attempting to achieve the final grind in a single pass.

Quality Indicators and Testing

Sharpness testing methods help determine when maintenance is needed. The paper test provides a quick assessment of blade sharpness—a sharp blade should slice through paper cleanly without tearing. For meat grinder applications, test cutting performance on raw meat samples to evaluate real-world performance.

Performance benchmarks establish standards for acceptable operation. Document grinding times, motor load, and output quality for comparison over time. Declining performance indicates maintenance needs before problems become severe. Regular performance monitoring helps optimize maintenance schedules and prevent unexpected failures.

When to replace vs. sharpen depends on blade condition and economics. Replace blades when sharpening no longer restores adequate performance, when damage compromises safety, or when replacement costs less than restoration. Consider the total cost of ownership, including labor, downtime, and performance impacts when making replacement decisions.

Common Mistakes to Avoid

Sharpening Errors

Incorrect angle maintenance is one of the most common sharpening mistakes. Maintaining consistent angles throughout the sharpening process ensures even edge geometry and optimal performance. Use angle guides when learning, and practice on spare blades before working on primary equipment. Inconsistent angles create weak spots and poor cutting performance.

Over-sharpening consequences can be as problematic as under-sharpening. Removing too much material weakens the blade and can alter its geometry. Sharp doesn’t always mean better—grinder blades need durability as well as sharpness. Stop sharpening when the blade achieves adequate performance, rather than pursuing maximum sharpness.

Uneven edge development creates inconsistent cutting performance and premature wear. Ensure both sides of the blade receive equal attention during sharpening. Count strokes and maintain consistent pressure to achieve uniform results. Uneven sharpening creates high-stress areas that can lead to chipping or premature failure.

Maintenance Oversights

Neglecting regular cleaning allows protein and grease buildup that can damage blades and create food safety risks. Develop cleaning protocols and stick to them consistently. Don’t allow meat residue to dry on equipment, as this creates ideal conditions for bacterial growth and makes cleaning more difficult.

Improper storage practices can undo all the benefits of proper maintenance. Store blades in dry, controlled environments with adequate protection from physical damage. Apply rust preventatives as needed, and avoid storage areas with temperature fluctuations that can cause condensation.

Delayed maintenance schedules often result in more expensive repairs and poor performance. Address maintenance needs promptly rather than waiting for convenient times. Regular maintenance prevents small problems from becoming major issues and ensures consistent performance when you need it most.

Usage Mistakes That Damage Blades

Grinding inappropriate materials causes immediate and severe blade damage. Never grind bones, metal objects, or other hard materials that can chip or break blades. Even small bone fragments can cause significant damage to sharp blades. When in doubt, remove questionable materials rather than risk blade damage.

Excessive force application creates unnecessary stress on blades and grinding mechanisms. Let the grinder do the work—forcing meat through the grinder can damage blades and create poor results. Use proper technique and maintain appropriate feeding rates for optimal performance and blade longevity.

Poor meat preparation creates unnecessary challenges for grinding equipment. Remove sinew, gristle, and other tough materials that can dull blades prematurely. Cut meat to appropriate sizes for your grinder capacity, and maintain proper temperatures throughout processing. Good preparation makes grinding easier and extends blade life.

FAQs

How do I know if my meat grinder blades are sharp enough?

Sharp meat grinder blades should cut through meat cleanly without crushing or smearing the fibers. Test your blades by examining the ground meat texture—properly sharp blades produce uniform, cleanly cut pieces with distinct edges. If the meat appears mushy, paste-like, or has a smeared appearance, your blades need sharpening. Another telltale sign is increased grinding time or motor strain, as dull blades require more force to achieve the same results.

Can I sharpen meat grinder blades with a knife sharpener?

While some electric knife sharpeners can be used for meat grinder blades, they’re not ideal for the task. Knife sharpeners are designed for different blade geometries and may remove too much material or create incorrect angles. If you choose to use a knife sharpener, select one with adjustable guides and gentle abrasive action. However, whetstones or professional sharpening services provide better results and greater control over the sharpening process.

What’s the difference between sharpening and honing grinder blades?

Sharpening removes metal to create a new edge, while honing realigns the existing edge without removing significant material. Honing can restore performance between major sharpenings by straightening microscopic edge deformations. Use honing steel or stropping compounds for regular maintenance, and reserve sharpening for when honing no longer restores adequate performance. Think of honing as tune-ups and sharpening as major maintenance.

How long should properly maintained meat grinder blades last?

Blade lifespan depends on usage patterns, maintenance quality, and blade material. Home users with proper maintenance can expect 2-5 years of service from quality blades. Commercial operations may require replacement every 6-12 months due to higher usage volumes. Carbon steel blades typically last longer than stainless steel but require more maintenance. Regular sharpening and proper storage significantly extend blade life regardless of material.

Is it worth sharpening cheap meat grinder blades?

The economics of sharpening cheap blades depend on sharpening costs versus replacement costs. If professional sharpening costs more than 50% of replacement cost, consider replacement instead. However, learning to sharpen blades yourself makes maintenance cost-effective for any quality blade. Even inexpensive blades benefit from proper maintenance, though they may not hold edges as long as premium blades.

Can rust be removed from meat grinder blades?

Light surface rust can often be removed with fine abrasives, naval jelly, or commercial rust removers like Evapo-Rust. More severe corrosion may require professional restoration or replacement. Prevention remains the best strategy—proper cleaning, drying, and storage prevent rust formation. If rust has created pitting or significantly weakened the blade, replacement is usually more cost-effective than restoration.

Expert Recommendations and Product Reviews

Top-Rated Sharpening Tools

Whetstone recommendations start with the King 1000/6000 Combination Stone, which provides excellent value for home users learning blade maintenance. The dual-grit design handles both major sharpening and final polishing in one tool. For professional applications, the Shapton Pro Series offers superior consistency and durability, though at higher cost.

Electric sharpener reviews highlight the Work Sharp Culinary E5 as a top choice for meat grinder blades. Its adjustable guides and gentle abrasive action make it suitable for grinder blade geometry. Avoid aggressive sharpeners designed for kitchen knives, as these can damage grinder blade profiles and remove excessive material.

Professional service providers can be found through Knife Rights directories or local kitchen supply stores. Many knife shops offer grinder blade sharpening services, typically charging $5-15 per blade. Professional services ensure optimal results and may identify wear patterns or damage that requires replacement.

Maintenance Product Recommendations

Cleaning solution reviews favor enzymatic cleaners for their effectiveness against protein deposits. Zep Commercial Enzyme Cleaner excels at breaking down stubborn residues without damaging blade surfaces. For routine cleaning, simple dish soap and warm water remain highly effective and food-safe.

Rust prevention products include food-grade mineral oil for basic protection and Corrosion-X for severe environments. VCI (Vapor Corrosion Inhibitor) papers provide excellent protection for long-term storage without leaving residues that might contaminate food.

Storage solution options range from simple blade guards to sophisticated climate-controlled systems. Wusthof blade guards provide excellent protection for individual blades, while professional operations may benefit from dedicated storage cabinets with controlled atmosphere systems.

When to Upgrade Your Blade System

Performance indicators that suggest upgrade needs include frequent sharpening requirements, persistent dullness despite maintenance, and visible wear or damage. If maintenance costs exceed 30% of replacement cost annually, consider upgrading to higher-quality blades that offer better longevity and performance.

Cost-benefit analysis should consider total ownership costs including purchase price, maintenance requirements, and performance impacts. Premium blades often provide better value through extended service life and superior performance, even at higher initial cost. Factor in labor costs for maintenance and potential downtime when evaluating options.

Recommended blade brands include Weston for home users seeking commercial-grade quality, and Hobart for professional applications. These manufacturers offer comprehensive blade systems with proven performance and readily available replacement parts.

Conclusion

Mastering how to sharpen and maintain meat grinder blades represents a crucial skill for anyone serious about meat processing, with the techniques outlined in this guide providing the foundation for peak grinder performance while extending blade life and ensuring food safety. The key takeaways center around establishing regular maintenance schedules, using proper sharpening techniques, and storing equipment correctly—whether you’re processing occasional batches at home or running commercial operations, these principles apply universally. Sharp blades preserve meat quality, reduce bacterial growth, and extend equipment life, making your grinding operations more efficient and productive. The investment in proper maintenance tools and techniques pays dividends through extended equipment life, reduced downtime, and consistent quality output that meets your standards every time you grind meat.